This iconic Finnish sniper rifle is the tightest-shooting factory gun we’ve ever tested

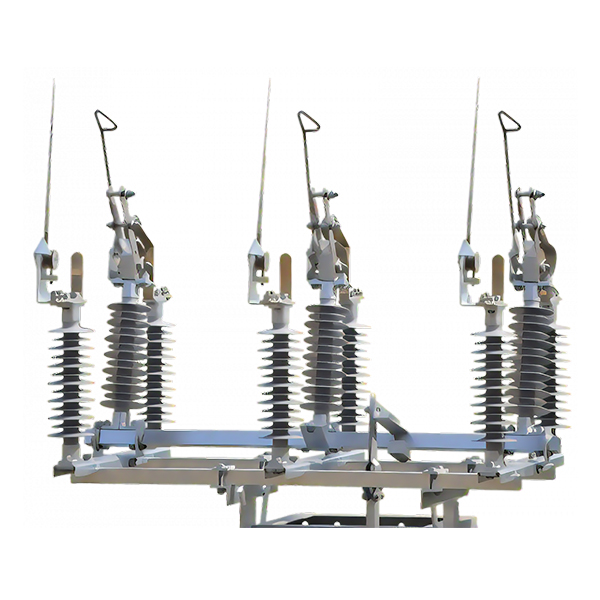

By John Snow | Published Dec 7, 2022 5:08 PM Porcelain Isolating Switch

The Sako TRG 22 A1 is the most accurate out-of-the-box production rifle I’ve ever tested. That puts it at the head of a list that includes many of the finest modern sniper and precision rifles made. But that’s only part of the story. As enjoyable as it is to see a rifle shoot bug-hole groups with nearly any ammunition that’s put through it, what I admire equally about the Sako TRG 22 A1 are its refined ergonomics and brilliant design.

Ergonomically, the rifle can be fit precisely to the shooter with easy-to-use, elegant controls. Moreover, every component on the rifle that can be manipulated by the user functions in a smooth and flawless fashion. Its craftsmanship is second-to-none.

The design of the Sako TRG 22 A1 is also a homerun. It is built to survive the most trying environments and is cleverly engineered so that the operator can easily service all its major components in the field with tools stowed within the chassis.

It is a remarkable firearm, and should you get to spend some quality time with one, you’ll understand why it is one of the best sniper rifles in use today.

The TRG 22 A1 is part of Sako’s family of sniper rifles. It is an offshoot of the TRG 22/42 models. The original-series TRGs (without the A1 designation) are heavy-barreled rifles that adjust for cheek height, length of pull, and other dimensions, although the stocks are fixed and do not fold. The 22 is for short-action calibers (.308 Win., .260 Rem., 6.5 Creed), while the 42 signifies long-action cartridges (.300 Win. Mag., .338 Lapua). Like the TRG 21/41 that preceded them, they have been popular with military and law enforcement agencies around the world, as well as with civilian shooters.

In 2018, Sako introduced the A1 series—the TRG 22 A1 and TRG 42 A1—which is built on an aluminum folding chassis that was first developed for the Sako M10 sniper rifle.

The key difference between the M10 and the TRG 22/42 A1 is that the M10 is a multi-caliber rifle with a quick-change barrel system. The TGR 22/42 A1 doesn’t have this capability (nor the M10’s significantly higher price tag) but it does have the M10’s fantastic ergonomics.

The chassis on a rifle performs two critical functions. First, it attaches to and supports the barreled action. The stronger and more rigid this connection, the better consistency, accuracy, and durability. Second, it creates the interface between the shooter and the rifle. The chassis’ geometry and dimensions dictate how naturally (or not) the shooter’s body conforms to the rifle. The more comfortable and relaxed the operator is behind the rifle, the better they’ll shoot.

Chassis that adjust for key dimensions like cheek height and length of pull are hardly new, but they aren’t all created equal, either. The chassis on the Sako TRG 22 A1 excels for its ability to fine tune these dimensions to a degree few other chassis can, allowing the shooter to really dial in rifle fit.

Cheek height, length of pull, and the height of the recoil pad adjust via low-profile buttons and tabs. Unlike many chassis that have bulky knobs or latches that can hang up on webbing, vegetation, clothing, and other objects, these controls are tucked out of the way. The TRG 22 A1 does a good job minimizing the possibility of snags.

Each of those dimensions adjusts in small increments to help the shooter get properly aligned behind the scope. Once the shooter has mastered the stock, these adjustments can be made quickly in the field to adapt to different shooting positions.

The Sako TRG 22 A1 comes with three grip inserts of varying thicknesses that are sized small, medium, and large. They position the web of the shooting hand either closer to or farther away from the trigger. The rifle ships with the medium grip installed and, while it will work for most shooters, it is worth trying the other inserts.

The inserts are held in place by a single T-10 Torx screw on the underside of the grip. Just back it out and the grip will slide right off. You can easily swap another in its place to test the fit.

As part of this fine-tuning process, the shooter can also change the position and orientation of the trigger. By loosening the T-10 on the bottom of the trigger, the operator can move the trigger forward and backward to tweak the trigger reach. It’s also possible to rotate the trigger shoe to one side or the other, if desired.

Between the grip inserts, the adjustability of the trigger reach and position, and the adjustability of the stock, the Sako TRG 22 A1 is customizable to a degree surpassed only by target rifles used in Olympic disciplines and similar competitions. There’s certainly no rifle built for military duty that outdoes it in this regard, though some rifles, like the Accuracy International AXSR, have similar flexibility.

The Sako TRG 22 A1 uses three fasteners to secure the action to the chassis. They are ¼-28 screws, which is the standard size used in Remington 700 pattern actions. But because the Sako’s three points of connection, instead of two, makes it the stronger system. I measured the amount of thread engagement on my rifle and found that the screws in the TRG 22 A1 have about a turn to a turn-and-a-half more engagement than you’ll find on a typical 700 action. That translates to about 33 percent more engagement per screw, which improves the rifle’s ruggedness and reliability.

One interesting thing about the Sako TRG 22 A1 is that the specs call for the action screws, and even the screw that holds the trigger housing in place, to be tightened to 133 in.-lb., which is significantly higher than you’ll find on nearly any other rifle. Tightening action screws between 50 and 80 in.-lb. is the norm, with 65 in.-lb. being the most common recommendation.

To access the middle and rear action screws, the user removes the trigger housing by inserting a T-25 Torx driver through a hole in the trigger guard and loosening a screw. To get to the front action screw, remove the tool kit in front of the magazine well.

The front action screw pins the rifle’s recoil lug in place. The lug is a small block that slides into a cut in the front of the chassis body. The top of the lug is flat, and fits into a machined flat on the bottom of the TRG’s action. The fit between the lug, chassis, and action is designed with a bit of play. When tightened, the three pieces self-center on each other to create a snug, stiff fit that doesn’t introduce any torque or stress into the system that could potentially degrade accuracy. It’s a smart, simple, and cost-effective system.

The folding portion of the stock was designed for stiffness as well. When the stock is deployed, there’s no detectable wiggle or play. When folded, the stock locks in position. A button on top of the chassis just in front the hinge allows the user to fold and unfold the stock.

While folders make rifle transport and storage easier, they do have one shortcoming: if mud or snow gets into the hinge mechanism, it can prevent the stock from locking open when unfolded.

During my evaluation, I purposely jammed the folded stock into the snow, and sure enough I couldn’t lock the stock open until I had cleared the hinge, which took some doing. This isn’t a criticism of the Sako TRG 22 A1, as all folders are prone to this, but it is something be aware of should you take a folding stock of any type into the field.

The octagonal-shaped handguard on the Sako TRG 22 A1 is held in place by two T-25 Torx crossbolt fasteners that pinch the rear of the handguard so it grips the cylindrical extension that juts off the front of the chassis. The rearmost fastener slides through a groove machined in the extension to properly index the handguard with the chassis. This also ensures that the handguard can’t work its way free even if the bolts aren’t tightened correctly.

A notch on the top of the handguard that fits around the Picatinny rail on the receiver also helps the handguard index properly.

The handguard extension doesn’t contact the barrel or the receiver, so pressure on the handguard doesn’t get transmitted to the free-floating barrel, which contributes to the Sako TRG 22 A1’s accuracy.

About the only criticism I have of the Sako TRG 22 A1 is that the handguard doesn’t incorporate an integral ARCA rail along the bottom. That feature has become common enough on precision rifles that it’s almost an expected feature.

The handguard has a full-length Picatinny rail along the top with a 30 MOA declination that mates up with the 30 MOA declination on the rail on the receiver. This allows for hassle free mounting of night vision gear and other items that need to be aligned with the rifle scope.

Sako machined numbers in every other grove, going from 20 to 52, to help return accessories to the same position after they’ve been removed.

The other seven flats on the handguard have M-Lok slots. There are more than enough to mount whatever gizmos you want. The rifle comes with four M-Lok rail sections: two short, one long, and one with sling mounts.

The chassis includes a hook on the underside of the buttstock to snug the rifle into the shoulder. It is well-shaped and can be used a couple ways. The hook can either fit in the web between the thumb and index finger or be hooked by the fingers of the non-shooting hand, depending on what the shooting position dictates. It attaches to the chassis via a Picatinny rail and can be removed and replaced with some other type of bag rider if desired.

The chassis has mounting points for a sling on the buttstock and just forward of the hinge above the grip. These mounts include QD sling sockets and Mil-sling lugs, so you can use either attachment system. The mounts are ambidextrous, which is a nice touch.

The rifle comes with a small M-Lok sling attachment that goes on the handguard for the front of the sling. It includes a QD socket and Mil-sling lug as well.

While the Sako TRG 22 A1 has been around for a few years, the Finns decided to spruce up the platform with the addition of some new Cerakote colors this year. My sample is in Tungsten Gray; the other new finishes are Olive Drab, Graphite Black, and Coyote Brown.

The TRG 22 A1 is one of the most intuitive and natural rifles I’ve ever shot. Everything functions smoothly without any hiccup or hesitation. Settling in behind it feels as good as reclining in your favorite easy chair.

The three-lug action is phosphate coated for corrosion resistance and lubricity. The bolt glides easily back and forth in the action with no chatter, vibration, or hang ups no matter how dirty it gets or how aggressively the shooter works it. The knob on the bolt handle is oversized and juts out at an angle that makes it easy to grab and it provides a lot of leverage to extract empties, cock the action, and chamber the next round.

During my time range sessions with the Sako TRG 22 A1, I put about 200 rounds through the rifle. Never once did I experience any failure to feed, extract, or eject rounds.

The rifle uses (of course) a Sako-style extractor and a plunger ejector. The ejector kicks the empties clear of the receiver in a snappy manner. To make sure the rifle does this with the larger magnum cartridges (.300 Win. Mag. and .338 Lapua) Sako added a second plunger ejector in the TRG 42 and TRG 42 A1.

The rifle runs off a proprietary 10-round magazine that accepts rounds easily—even with gloves on—and slides into the magazine well with minimal effort. The inside of the mag well is slightly beveled which helps guide it. The magazine locks into place in a very positive manner and doesn’t require any extra pressure to engage the latch.

The paddle to release the magazine is located just in front of the trigger guard and is easy to manipulate. When pressed forward, the magazine drops free without hesitation.

Even though this is exactly how a detachable box magazine system is supposed to work, they often don’t—even on top-end rifles with hefty price tags. So when one operates perfectly, you know you’re dealing with a well-made rig.

Two-stage triggers are the norm on sniper rifles, and the Sako TRG 22 A1 is no exception in this regard. The trigger is user-adjustable with a pull weight that can set between 2.6 and 4.6 pounds.

I turned mine down to its minimum break weight, which came in at 2 pounds, 10 ounces. To adjust the trigger, insert a Torx T-10 driver through the smallest of the three access holes in the trigger guard and turn the adjustment screw counterclockwise.

The initial take-up on my trigger requires a touch over a pound of pressure to engage the second stage. Once the slack is removed, the trigger exhibits no creep before it trips with that extra pound or so of pressure.

The crisp, consistent break provides excellent trigger control and, along with the ability to fine-tune the trigger geometry discussed above, contributes significantly to the rifle’s exceptional accuracy.

The safety on the Sako TRG 22 A1 is a paddle located within the trigger guard that toggles back and forth. The paddle requires deliberate, but not excessive, pressure to switch between “safe” and “fire,” and it gives good tactical and audible feedback when moved. When pushed forward, the rifle is in the fire position.

When engaged, the safety mechanically blocks the trigger, which is what you want, and locks the bolt in place. As with other features on the rifle, the safety can be worked while the operator is wearing gloves.

The Sako TRG 22 A1’s top-flight ergonomics, excellent controls, and weight—fully kitted out with scope, bipod, and suppressor, mine tipped the scales at 17 lb. 4 oz.—combine to give the rifle excellent recoil management.

With the chassis properly adjusted and the shooter square behind the rifle, it isn’t difficult to maintain your sight picture after breaking the shot. I found it easy to spot impacts and misses and stay in the glass while running the action.

My first range session with the rifle was an eye-opening experience. I’ve shot and owned plenty of Sakos over the years, including the exceptional M10 sniper rifle when it was first introduced, so my expectations were pretty high. That said, the first 40 rounds I put through this 6.5 Creedmoor amazed me.

I was at an outdoor range in Colorado with temperatures in the upper teens and a fairly brisk crosswind blowing up the canyon. I bore-sighted the rifle, aimed at the center bull, and hit low right next to one of the other aiming points.

I shot the remainder of that 5-shot group, adjusted the point of aim on the Leupold Mark 5HD 5-25×56, and shot another. I repeated this with three other loads, placing two 5-shot groups on paper for each. I had one shot I pulled on the final group due to heavy mirage coming off the suppressor, so I put an extra round downrange and discounted that one errant impact.

The average of those eight 5-shot groups was just .384 inches. That was with four different factory ammo loads with bullet weights from 130 to 147 grains. I’ve evaluated rifles for decades and never had a factory gun that shot to this level. Some of my competition rifles shoot this tight, but they are doing so with carefully constructed handloads, not factory ammunition.

One interesting thing I noticed on the target was that the first 5-shot group with each load was larger than the second 5 five-shot group.

We’re all familiar with the idea of fouling a rifle: After a thorough barrel cleaning, it can take a few shots before the rifle starts shooting to its potential. The difference in group sizes from a sparkling clean barrel and one that’s had a dozen rounds through it can be dramatic. Sometimes you’ll see the same effect, though to a lesser degree, when you switch from one type of bullet to another.

In my experience this is most pronounced when switching between standard jacketed lead bullets and copper alloy “monometal” bullets. It seems barrels sometimes need to acclimate to the specific metal composition of the bullets they’re shooting.

Keeping that in mind, it was striking that the average of the first groups I shot with Sako TRG 22 A1 was .502 inches—still an impressive result—but that the average of the second groups was just .266 inches, which is really amazing.

While this data is suggestive, I wouldn’t deem it definitive. To really test the concept that you should foul a rifle when switching from one bullet type to another would require a much larger data set. It is something we plan to look at in the future.

Included in those groups was one that measured a scant .051 inches—by far the best group of the many thousands I’ve shot over the decades. That was with Hornady’s 147-grain ELD-M ammo. That ammo also happened to shoot the largest group with the Sako TRG 22 A1, which was .558 inches.

A lot of the credit for this accuracy has to go to the barrel. The Sako TRG 22 A1 has a 26-inch barrel that’s cold-hammer forged. In 6.5 Creedmoor it has a 1:8 right twist and is threaded 5/8-24 at the muzzle for the American market.

In .308 Win., the rifle has a 26-inch barrel threaded 5/8-24 as well. While the magnum cartridges in the TRG 42 A1 series (.300 Win. Mag. and .338 Lapua) have 27-inch barrels. The .300 Win. Mag. is threaded 5/8-24, while the .338 Lapua has the European standard M18x1 thread pitch.

Sako made it easy for shooters to take care of this rifle, whether in the field or at a bench. The designers went to great lengths to make sure an operator can keep the rifle in working condition no matter what. It’s reassuring to know that just about any problem can be addressed with very few tools.

The rifle contains an on-board tool kit, located in the polymer palm swell underneath the handguard and just in front of the magazine.

To access the tool kit, remove the bolt from the rifle and use the Torx T-25 bit machined into the bolt knob to detach the kit. Sako smartly designed it with a captured screw, so you can’t lose the fastener.

Contained within the kit are three Torx keys: a T-25, T-15, and T-10. With them you can tighten and service any of the critical fastners on the rifle. They allow you to remove the handguard, adjust the trigger pull weight and trigger geometry, swap out the grip inserts, tighten the action screws, reconfigure the sling attachments, mount the included M-Lok rails, and remove and refine the position of the recoil pad.

The bolt can also be taken apart and serviced in the field. The bolt shroud can be twisted off by hand giving access to the firing pin and firing-pin spring, and reassembled the same way. Sako includes a tool that makes this takedown and reassembly process easier to perform, but anyone with moderate hand strength won’t need it.

The Sako TRG 22 A1 is an impressive rifle, even when measured against its peer group that includes some really fabulous rifles made by Accuracy International, Barrett, and others.

While this review discusses the various features of the rifle in-depth, the experience of shooting the TRG 22 A1 is a bit more difficult to capture. The rifle is more than the sum of its parts in this respect.

Sako’s engineers did a fabulous job creating a rifle that serious shooters will appreciate and enjoy, whether they are carrying the gun as part of their job or just using it for competition or other recreational purposes.

Expensive? Yes. But it isn’t as costly as many custom rifles being sold today and, with precious few exceptions, it will out-shoot every one of them.

John B. Snow is Shooting Editor of Outdoor Life, where he oversees the publication’s firearms and shooting coverage. This includes gear reviews, features on technical innovations, stories on shooting techniques and general hunting coverage with the occasional fishing story thrown into the mix.

Want more hunting and fishing stories?

Sign up to receive our emails.

Isolating Switch Articles may contain affiliate links which enable us to share in the revenue of any purchases made. Registration on or use of this site constitutes acceptance of our Terms of Service.